Favourites

Sign in to your account

By adding to Favourites, you can…

- Save products or resource documents you view regularly

- Save time with quick access to frequently viewed items

Please sign in or create an account to add to your Favourites.

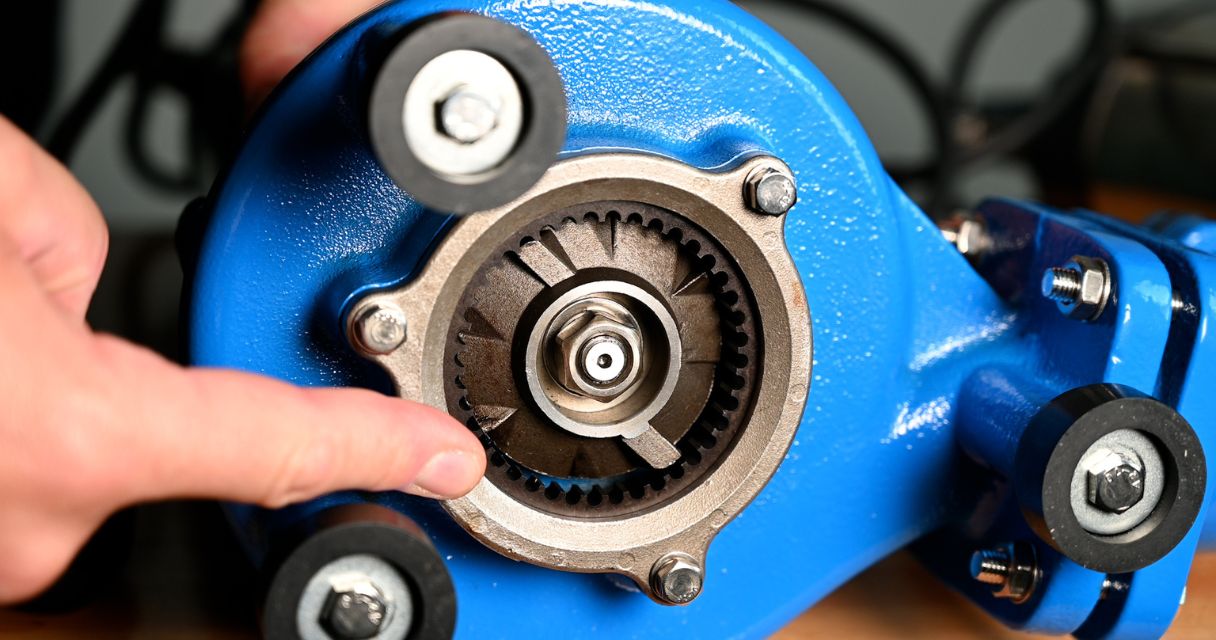

Adjusting a Bromic gas regulator ensures that gas-powered appliances receive the correct pressure for optimal performance. The process varies depending on the type of regulator (LPG, natural gas, single-stage, or dual-stage), but the general steps are similar.

1. Identify the Adjustment Screw

Locate the pressure adjustment screw on the regulator (typically covered by a plastic cap that needs to be unscrewed). Some Bromic regulators use spring-loaded mechanisms to control gas flow.

2. Turn On Gas & Test Appliance

Slowly open the gas supply and ignite the appliance.

Observe the flame pattern and appliance performance. A steady blue flame indicates proper adjustment.

3. Make Small Adjustments

While the appliance/s are running, measure the dynamic pressure and adjust as required.

Increase Pressure: Turn the screw clockwise (+) to allow more gas flow.

Decrease Pressure: Turn the screw counterclockwise (-) to reduce gas flow.

Adjust in ¼-turn increments, checking the pressure gauge after each adjustment.

5. Check for Gas Leaks

Mix soapy water or a leak detector such as LA-CO Visu-glow Fluorescent Leak and apply it to the regulator connections. If bubbles form, there is a leak – tighten connections or replace seals.

6. Secure the Adjustment & Monitor

Once the correct pressure is set, replace the adjustment cap (if applicable). Monitor the appliance over time to ensure consistent performance.

1. High-Pressure Gas Enters the Regulator

Gas flows from the supply source (LPG cylinder or natural gas line) into the regulator.

This gas is at a much higher pressure than what appliances can handle.

2. Diaphragm & Spring Mechanism Adjusts Flow

Inside the regulator, a spring pushes against a diaphragm, keeping the valve partially closed.

When the outlet pressure drops, the spring opens the valve slightly, allowing more gas to flow.

As the pressure rises, the diaphragm pushes back, closing the valve to reduce flow.

3. Pressure Stabilization

The regulator constantly adjusts the valve opening to maintain a consistent outlet pressure despite fluctuations in the gas supply or appliance demand.

Some regulators have an adjustment screw that allows users to fine-tune the pressure.

4. Safety Venting (If needed)

If pressure builds up excessively, all regulators include a safety valve/vent to release small amounts of gas safely. Ensure this is free of obstruction at all times.

The plumber should check what safety features are required for the installation of each regulator. Additional safety valves can be installed if required – such as an OPSO Valve.

A gas regulator is a device that controls the pressure of gas flowing from a high-pressure source (such as a gas cylinder or supply line) to a lower, usable pressure for appliances. It ensures a consistent and safe gas flow, preventing overpressure that could damage equipment or cause safety hazards.

- Run lock buttons for finger-free use: The run-lock button on Bromic gas torches allows for finger-free operation, providing enhanced convenience and reducing hand fatigue during extended use.

- Pressure regulation: Pressure regulation in Bromic gas torches ensures consistent flame performance, even when working at different angles or with varying gas levels, enhancing precision and reliability.

- Flame adjustment: The flame adjustment feature on Bromic gas torches allows users to precisely control flame intensity. This makes them appropriate for a versatile range of applications, from delicate soldering to heavy-duty heating.

- Child locks: The child lock feature on Bromic gas torches enhances safety by preventing accidental ignition, offering peace of mind during storage and use.

Having the proper accessories for a complete torch kit ensures optimal performance, safety, and versatility for any task. Bromic simplifies the process by providing all essential products in one place, offering reliable, high-quality solutions tailored to your needs, including:

- Gas cylinders: Disposable gas cylinders are compact and lightweight, designed to make work easier for trade applications or confined spaces. We provide a range of disposable gas cylinders ideal for jobs including soldering, brazing, cutting, cooking & fine product repair.

- Gas regulators: Bromic’s gas regulators are precision engineered for welding, cutting and brazing applications with gas cylinders. Our gas pressure regulators are constructed by machine brass and include an accurate flow gauge for easy reading.

- Oxy kits: We supply a range of gas soldering and brazing kits that can be used with various gas applications including brazing, soldering and cutting copper pipes. Instead of using a traditional oxy-acetylene setup, our kits are designed to be used with Oxygen and Map-Pro gas cylinders for extra safety, affordability and lightweight convenience.

- Solder: Bromic’s offers electrical rosin core and acid core solder. They are designed for applications such as use on metal gutters, tin work, small motors and more. They also eliminate the need for flux.

- Flux: Flux is the ultimate flux for all copper soldering applications. This all-weather water-soluble paste leaves no residue in water piping and contains no zinc chloride, reducing corrosion concerns.

- Swivel head: Bromic Swivel head torch helps users easily solder, safely apply a horizontal flame and braze in tight and awkward spaces with one hand. The 360° horizontal swivel head provides greater accessibility, and a fully-adjustable swirl flame produces hot, efficient heat for fast soldering times. It is important to keep the gas cylinder vertical while in use.

The handle type of a gas torch plays a crucial role in its usability, comfort, and application efficiency. Ergonomic handles are designed for prolonged use, reducing strain and improving control, making them ideal for precision tasks like soldering or brazing. In contrast, rugged, heat-resistant handles are better suited for heavy-duty industrial applications.

Gas torches with compatibility for hose attachments provide greater flexibility and mobility. They are especially useful in settings like workshops or outdoor projects, where direct cylinder attachment can be restrictive. These torches are perfect for accessing tight spaces or working on large surfaces without the burden of carrying the gas source.

Bromic offers solutions such as the Sievert Promatic handle and Sievert Pro 88 handle as well as Bromic swirl flame hose torch that are tailored to such versatile requirements. They offer a high level of performance and convenience.

The flame type is the size, shape and type of flame that the hand torch produces. Different flame types are suited to different applications. Types of flames include:

- Micro (Precisions) Flame: A small and precise flame, ideal for detailing tasks that do not require significant heat. It’s used for precise work such as in electrical soldering and jewellery making.

- Pencil Flame: A sharp, narrow flame suited for medium precision work. This flame is ideal for general-purpose soldering such as jewellery making, heat shrinking or soldering electronics.

- Webbed Flame: This flame has a broader, web-like pattern. It distributes heat evenly over a larger surface, suitable for soft soldering or brazing tasks on medium-sized pipes or components.

- Jumbo / Jet Flame: A powerful and focused flame with higher heat intensity. This flame is suited for general home and DIY project tasks such as soldering copper pipes, heat shrinking, cooking and lighting grills.

- Swirl Flame: A swirl flame is created by a nozzle that induces a swirling motion in the fuel-air mixture. It produces a steady higher heat flame. It’s tightly focused flame suitable general home and DIY projects.

- Ultra Swirl Flame: The ultra-swirl flame has a nozzle that enhances the swirling action of the fuel-air mixture. This creates a more aggressive, faster-spinning flame that delivers even more heat than a standard swirl flame. This flame is also suitable for home and DIY projects, as well as brazing copper pipes and other tasks.

- Soft (Wide) Flame: A torch with a wide opening can produce a soft, wide flame. The soft flame allows a large surface area to be heated, without overheating or burning material. This flame is suited for heating, as well as heat shrinking and cable work.

- Cyclone Burner Flame: This type of flame is designed for soldering and brazing pipes. The flame is able to wrap around a pipe, allowing for better heat distribution along the diameter.

- Power Burner Flame: A power burner flame also has a wide opening, with a much longer flame reach. The wide flame lowers the risk of overheating or burning material. The long flame reach and wind-resistant capabilities makes it suitable for professional heating, waterproofing and welding applications.

When selecting your Fuel, it is good to understand the different applications for each fuel source.

- Electric: These soldering irons are great for light to heavy soldering, DIY jobs and electrical repair.

- Butane: Well-suited for soldering electronic circuits, heat shrinking, cooking and jewellery design and repair.

- Propane: Ideal for smaller soft soldering jobs, removing paint, caulk or putty and loosening rusted nuts and bolts.

- MAP//Pro™: Designed for larger, hotter jobs such as soldering large-diameter copper pipe, brazing, or heat-treating. This fuel is ideal for plumbing, soldering & brazing as well as automotive repair and is ideal for professional tradespeople such as HVAC techs and plumbers.

- Oxygen & MAP//Pro™: When oxygen is combined with MAP//Pro™, this combination of fuel sources is hot enough for brazing, light welding, hardening steel, and thin metal cutting. This fuel combination is ideal for professional tradespeople such as HVAC techs and plumbers.

Portability: Lightweight and compact, gas torches can be easily transported and used in various locations. This makes them ideal for both indoor and outdoor tasks.

Versatility: Suitable for a wide range of applications, including soldering, brazing, heating, cooking, and even paint stripping.

High Heat Output: Gas torches deliver intense heat that can quickly reach the temperatures needed for demanding tasks like welding and metal cutting.

Precise Control: Features like adjustable flame settings and pencil flames allow for meticulous work on delicate projects requiring high levels of accuracy.

Ease of Use: Many gas torches include user-friendly features such as piezo ignition systems, ergonomic handles, and run-lock buttons for finger-free operation, enhancing convenience and safety.

Rainwater harvesting offers many benefits, including:

- Savings: Using rainwater as a natural source of water can reduce your utilises bill, offering significant savings over time.

- Required water source: In some areas, rainwater harvesting can be a crucial source of water drinking and other uses. It is recommended in several jurisdictions around Australia to reduce reliance on main water supplies.

- Environmental benefits: Rainwater harvesting offers environmental benefits including decreased stormwater runoff and reduced near for main water usage. When you take advantage of rainwater harvesting, you can contribute to more sustainable water usage.

STILL HAVE QUESTIONS?

If you have searched our website, document library & FAQs and haven’t found the information you need, please contact us to resolve your query. This will allow us to continually improve the data we share here and elsewhere on our website.